This is a quick little tech tip for those of you who have ever had trouble getting your nitro or gasser model engine properly aligned with the clutch stack. First off, what are the symptoms of a misaligned engine and clutch stack? Well, on the bench you can feel a roughness or unevenness when rotating the starter shaft with your fingers. This is a sign that the clutch on the end of your crankshaft is not centered inside your clutch bell and, as a result, you get a chunky feeling in the clutch one-way bearing when you spin the shaft. The problem with this is that, given enough time, you can wear your clutch and clutch liner unevenly, which can lead to failure of one or both of these components. Also, this can lead to vibrations that may affect your gyros or flybarless units and also damage your clutch stack bearings. So, it’s always a good idea to make sure that you get your engine installed with proper alignment.

The way to do this is actually quite simple:

1. Make sure that your clutch stack bolts are fully tightened so that the block can not move in the frames.

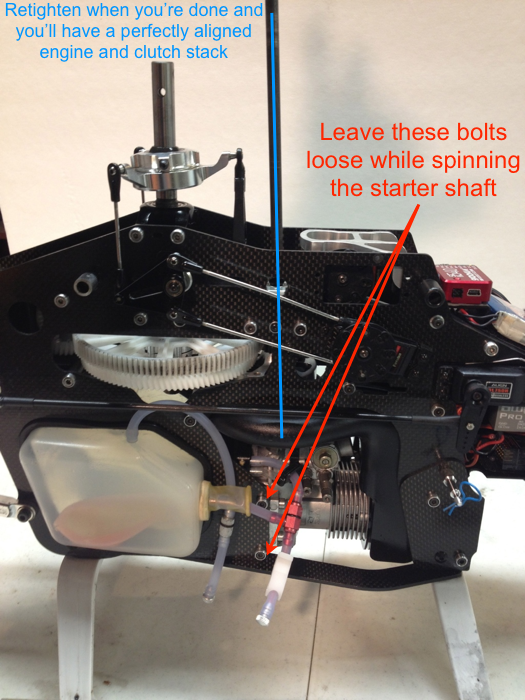

2. Get your engine installed in your airframe as shown in the picture above, but don’t tighten down the engine mount bolts. This allows you to move the engine around a little and is the key to getting the alignment nailed perfectly.

3. Now, this is the neat part. Take your electric starter and place it in the starter hex adapter as if you were going to start the engine. Though it shouldn’t need to be said, please make sure that you’re fuel and ignition systems are secure in such a way that the engine will not start and you won’t be blowing nitro fuel all over yourself! 😉 When you’re ready, turn on your starter and let it run for a few seconds. Since the engine mount bolts are loose, the engine will and clutch will move into an orientation that resists the starter spinning motion the least. This is also the orientation in which your alignment is best!

4. Now, it’s preferrable to have another person to help you at this point because you now want to tighten up your engine mount bolts while the whole stack is aligned and the best way to do that is while you’re still running the starter. If you’re alone though, then don’t worry…spin the starter for a few seconds and then tighten a bolt. Spin it for a few more and then tighten another bolt. Rinse and repeat until your engine mount bolts are nice and tight and then recheck the feel of the starter shaft with your fingers.

5. If it feels like it’s still a bit chunky, then this may indicate that your clutch block is out of alignment with respect to the play that you have in your engine mount bolts. To fix this, you can loosen your clutch block bolts to the point where the block can be moved only if you put a little muscle into it. You don’t want it flopping around like the engine…then go back to step #2 and try again!

This is a really easy trick once you get the hang of it and will make all the difference in the world if you’ve been suffering from misaligned power systems. Remember, it can be done with any size of nitro bird or with a gasser too with either the pull-start or the starter shaft. I hope that this helps others as much as it’s helped us. Spread the word!

– Justin