BK Servo DS-7001HV Review

Written by Jessie Salmonson

First off, I’d like to give a huge thank you to Bert and Suzi Kammerer at BK Servos for making this review possible. I was really excited when I heard I was going to have the opportunity to take a look at these BK servos. I have been hearing so many good things about them and the specs look great as well. So lets get started!

What’s in the Box

Right when you get these servos, you will notice that they come nicely packaged in a small plastic box. Now this isn’t your typical servo packaging for standard sized servos, I am used to the small hard plastic cases that open, but this provides plenty of protection and they are very easy to dispose of. The servo is held into place with a foam insert that holds it tightly so it can’t be damaged during shipping. In addition, the foam also has a spot to secure the wiring and everything else in the box.

In the box comes your standard selection of goodies including a couple servo horns as well as rubber grommets and brass sleeves. I will not be using the supplied servo horns as I already have some on my heli, besides these are a little on the small side. Now, if I had a heli that used some sort of carbon fiber reinforcement on the servo arms, then these would work just fine, but for a direct-to-swash application with no reinforcement they are too small. Overall the gear that comes with the servo is very standard, so no surprises here.

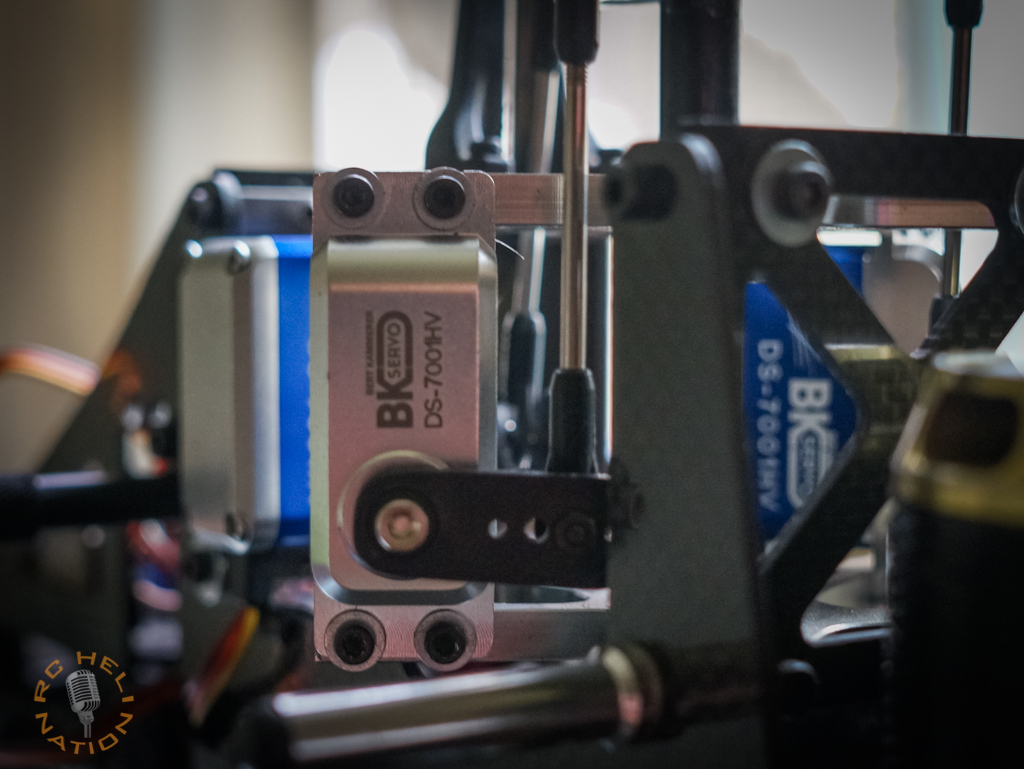

Upon initial inspection it’s easy to see the work that went into designing this case, as it’s absolutely gorgeous. The servo case is a fully CNC’d aluminum design that has some blue anodizing on it in the center of the case. Honestly these servos have an extremely nice fit and finish which makes them very visually appealing. The servo wire coming out of the servo is 11 inches long, which compared to other servos I have is roughly the same.

This should make the installation a breeze since i’m not going to need to change the way I route the wires. The servo is held together by four screws that have a philips heads on them. Honestly I would have really like to see a screw that we could loosen with our standard drivers but with the right philips screw driver these came out no problem so I don’t forsee any issues getting these servos apart during gear swaps. These servos are definitely sexy enough to go in my heli!

When we take a look at the specs these servos are nothing shy of impressive especially when you consider the price. The BK servos have a coreless motor and are rated for full 2S lipo voltage (8.4V). The torque rating for these servos is 295 in-oz. In addition to having plenty of torque these servos are blazing fast having a rating of 0.049 seconds per 60 degrees of travel. What this means for those that aren’t familiar with this rating is the servo can travel 60 degrees in a mere 0.049 seconds. When you take a minute to think about that you realize how impressive that number is. I did quite a bit of looking around and I could not find another cyclic servo that was faster than this one. In fact this is a similar speed to some tail servos. That being said there may be a faster cyclic servo out there, just not one I could find.

There have been tests to confirm some of these numbers. Below is a video or a servo test conducted by Cris Trebbi. As we see in the video, the servo lines up nicely with the rated spec. Thanks Chris for taking the time to perform this test!

There are a couple smaller things I would like to point out. One thing I really like to see is the beefy support right where the wire exits the servo case. When you consider the amount of vibration and abuse these things are subject to, it’s nice to see this wire so well supported. Next is the smoothness of the gear train. Two out of my three servos were perfectly smooth and didn’t have the slightest hint of a rough spot. On one of the servos, there was a very slight tight spot in the gear train when rotating the servo by hand. It wasn’t anything I was concerned about as it wasn’t notchy at all. After two or three flights this did go away so it must have just been the grease working in as everything seated.

Installation and Setup

Like previously mentioned, since the wires are of average length, installation was a breeze since I routed the wires the exact same way I always do on my Compass 7HV. The installation was very straight forward and I opted not to use the grommets, but directly mounted the servos to the heli. Now, I have heard both sides of this argument as some say you should always use grommets to limit the amount of vibration that gets transmitted through the case of the servo. In addition, using the grommets does make it easier to align the servo making sure they are straight in your helicopter.

Even with all of this being said, I hate the slop that the grommets introduce. To me it seems counter-productive… We spend so much time making sure these helis are mechanically sound and well built, so why would we want to intentionally add slop especially on an electric heli? By not using the grommets, I can actually decrease the running temperature of the servo if the mount is metal as well. When no grommets are used, you basically turn the entire servo mount in to a giant heat sink helping to keep things cool. So my rule of thumb is on an electric heli I don’t use the grommets and on a nitro I use them due to the higher vibrations.

For this review, I am running the servos off of a straight 2s lipo as a power source and will be using a mini VBar as my flybarless controller. By using a 2s lipo, I will be able to achieve the maximum performance that the servos can provide. Once, I had the servos installed in the heli I redid my setup so that I could get the arms at 90 degrees and so on.

The first thing to check was to confirm that the VBar was set for 1520us/333hz, which is the pulse width and frequency of these servos. The BK servos did require a little trim in the vbar to get those arms at a perfect 90 degrees, but honestly this is going to be the same for any brand unless they have the clamping arms. During setup the one thing I noticed was these servos do make some noise even when they are just sitting there. I wouldnt say its a significant amount of buzzing, but it’s definitely present. With that being said, this isn’t a negative thing… I’m more just pointing it out to say thats it’s normal and I’ve experienced this with both of my sets of these servos. Once I had the servos installed and the heli all set up it was time to go fly!

Flight Performance

For the first couple flights, I really wanted to get an accurate comparison to the previous servos I was using. To do this, I didn’t change a single gain in the Vbar for the first five flights. Right away, I could feel the difference in speed and power on these servos. For those of you that fly VBar, you probably know what paddle simulation is – it increases the responsiveness of the heli off of center stick. On the first flight with the BK servos, it immediately felt like I had added some paddle simulation even though I hadn’t, meaning I could clearly feel the off-center response.

Not only could I feel the speed, but I could feel the boost in torque as well. Before I switched to these servos, I had struggled to get crisp stops and perform continuous piro tic tocs, but once the BK servos were installed I noticed certain maneuvers such as piro tic tocs became easier. Now, keep in mind I didn’t change the head speed or any settings in the VBar. In addition, this extra stopping power lead to a few head bobbles in maneuvers such as tic tocs that weren’t there before. So at this point, I am extremely pleased with the flight performance because it’s always nice when you notice a clear performance increase when installing some new gear.

Ok, you might be saying “Well I can’t do piro tic tocs so would I really feel the increase in performance from these servos?” I would say that if you are doing tic tocs or any maneuvers where you are requiring the heli to stop quickly and change directions you will be able to tell the difference.

After those initial five flights, I did end up making a couple changes to the VBar. In the end, I went down about eight points on the main head gain. This was necessary to get rid of the bobbles that were a result of the extra torque and speed. Tuning this was quite simple as the bobbles were the only negative tendency, I just kept decreasing the gain by two points at a time until they went away. To address the off-center response, I turned down the paddle simulation by about five points as well. This brought the heli back to a comfortable speed and made it manageable in moves like tic tocs. Other than changing these two settings, no other tuning was required and even to this date I haven’t made another change.

Not only are these servos strong and quick they also don’t draw very much current at all. I did multiple tests and found the average milliamp draw per flight was 175 mAh. For me, this is a very important spec for servos because this means I will be able to get more flights without having to recharge a receiver pack. For this review, I was using a 1600 mAh receiver pack and with this small current draw, I could easily get 4 flights before recharging. If I wanted to really push it I could get even more without any issues.

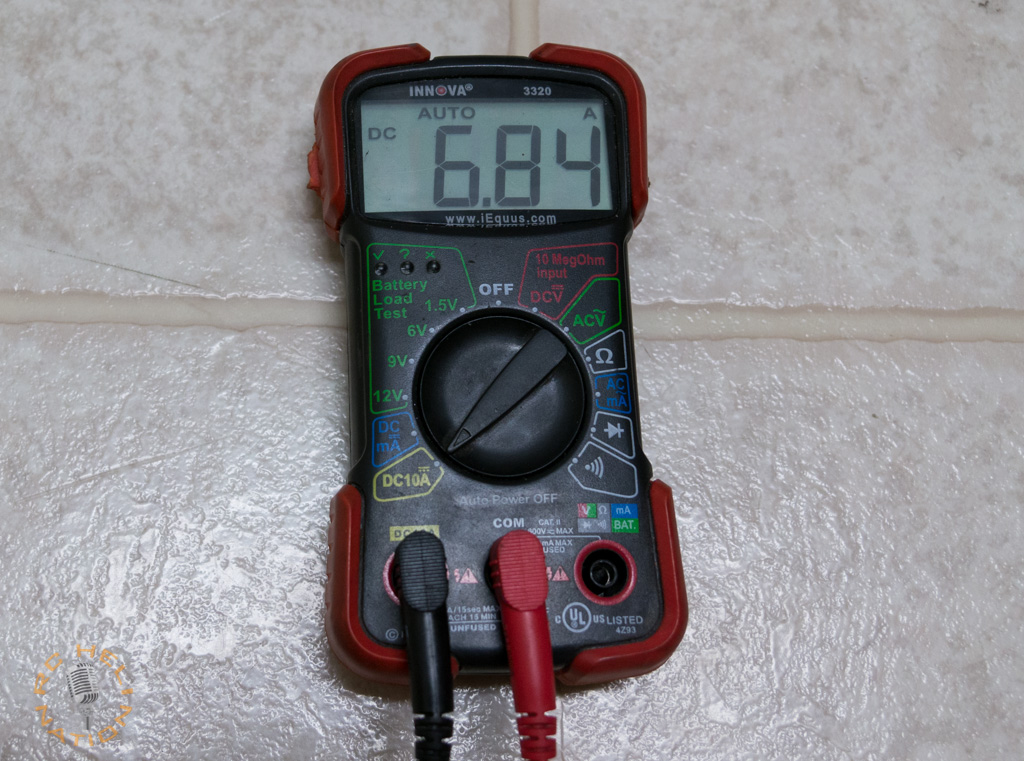

In addition I tested the current draw of the servos on the bench while holding to the head and and moving the sticks as quickly as I could. To provide resistance to the head, I used my hands to place a downward force on both blade grips and trust me – I wasn’t going easy on them. For this test, I unplugged the tail servo from the VBar so I could focus in on just the current that was being drawn by the 3 cyclic servos. I found that an average current draw was 0.87 amps while just jiggling the sticks under no load. When providing resistance to the head I found a maximum current draw of 7.2 amps.

The picture below shows a reading of 6.8 amps, which I believe is much more representative an average draw during this high resistance test. Keep in mind that the 7.2 amps was a peak reading, not an average. This is a huge win in my opinion because this means that you can run them off of just about any BEC out there without fear of overloading the system and suffering a voltage drop which could cause a number of other issues. This also means that they will work with any FBL unit! Yes, even a mini VBar will handle this without having to worry about pushing the power bus beyond its limits.

As of the time of this review, I have 75 flights on the set of servos that is on the 7HV and roughly 80 flights on the set that is in the Synergy N7. I’m still extremely pleased with the flight performance that these servos provide. Unfortunately, I have to report that the servos do have a very slight amount of slop in the gears, but before you freak out, let’s put this in perspective, as I really hate using the word slop. With the servos powered, if I place some pressure on the servo horn trying to move it up and down there is a very slight click. It is so minor that it won’t affect the flight performance in any way, but it was not present when the servos were new, so it is worth mentioning.

I am definitely going to continue putting flights on the servos and won’t replace the gears until they strip. One other thing I have noticed is the operating temperature of the BK servos as compared to my previous servos. Now, I didn’t have a temperature gun with me at the field so this is just qualitative, but at the end of a 4.5-minute flight the servos came down barely above ambient temperature. Keep in mind this isn’t a scientific measurement but you can tell by touching the case if something is way above ambient and I can say these were not.

It wouldn’t be a complete review if I didn’t do a crash performance section, right? For those of you that heard the N7 review, you know that I crashed that heli during the review. Well guess which servos happened to be in that heli during the crash? Thats right! BK Servos! Just to fill everyone in, this was a pretty bad crash, as the heli went in directly on the head. In my opinion, this has to be one of the hardest crashes on the servos because all the initial force is directed straight to the servos in a direct to swash setup. With all this being said, I was still really happy to find only one set of servo gears had stripped and that the other two servos were completely fine.

Switching out and replacing the servo gears was very straight forward and was similar to nearly any servo on the market. Once I had the new gears installed, I used some white lithium grease to lubricate the gears. When the servo was back together, it was good as new and the new gears were extremely smooth with zero slop in the gear train.

When picking a servo, one thing that I really like to consider is the cost of the replacement gears. Let’s face it – if we own a set of servos long enough you’re bound to strip the gears every so often in a crash. In this category the BK servos are a definite winner. I was pleasantly surprised to find that a brand-new set of gears only cost $24. At this price point, I can definitely afford to keep multiple sets of gears on hand in case of a crash, which means no down time at funflies! When looking at the big picture and taking into account the initial cost of the servos as well as replacement gear costs these servos get a big thumbs up from me!

Conclusion

When looking at the big picture, I truly think it’s going to be hard to beat these servos. Taking in to account the 295 in-oz of torque and a speed of 0.049 seconds, these servos are going to work well in a variety of applications. I know for myself the next time I go to build a new heli or replace an old worn out set of servos, these will be near the top of my list. At $99 for each cyclic servo and only $24 for replacement gear sets, they are near the less-expensive end of the spectrum when it comes to full size servos. This makes these servos a perfect option even for a budget build! I should also mention for those of you looking for brushless servos BK servo recently released brushless models. Although the price of these brushless servos is going to be a little higher, the specs do look great. Although I haven’t personally flown these servos if they are anything like the DS-7001HV I would think you can’t go wrong.

Once again, thank you to Bert and Suzi at BK Servos for the opportunity to try these servos out. Hopefully, if you were looking for a new set of servos or were on the fence about the BK servos, this review will provide some insight that helps the decision along. If you guys have any questions about the review please feel free to shoot me an email at .

-Jessie